mit BBD-Funktion (Break-Down-Detect) zur Erkennung durch Verunreinigung verursachten Isolationsdefekten

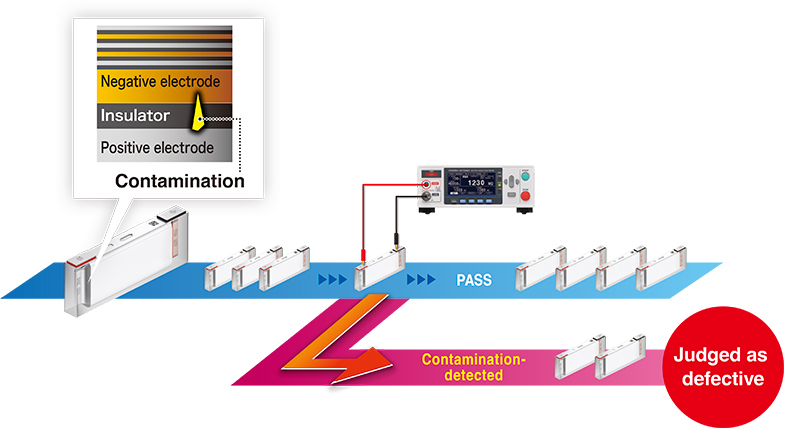

Detecting minuscule insulation defects caused by contamination (Break Down Detect function)

The BDD function is a proprietary testing function that can detect minuscule internal short-circuits caused by contamination (with metallic matter) at the stage before battery cells are filled with electrolyte. By identifying and eliminating defective parts at an early stage in the production process, the BDD function helps prevent the risk of hazards such as fires and accidents caused by heating after battery shipment. In addition, minuscule internal short-circuits in cells accelerate battery degradation. The BDD function will contribute to the production of batteries with greater durability and electrical performance.

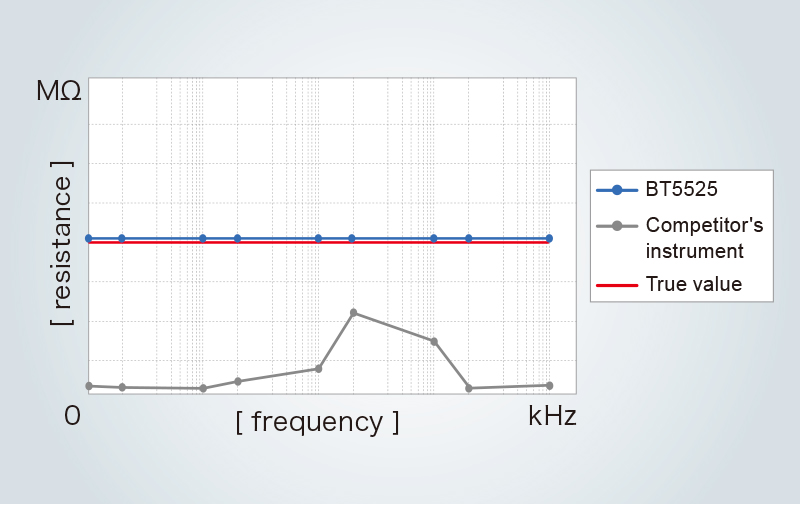

Stable insulation resistance testing, even in noisy environments

Hioki succeeded in significantly reducing the effects of external noise by drawing on insulation resistance tester measurement technology and design expertise cultivated over many years.

As a result, the BT5525 can perform stable, variation-free insulation resistance testing at a level of quality that lets its detect internal short-circuits caused by contamination.

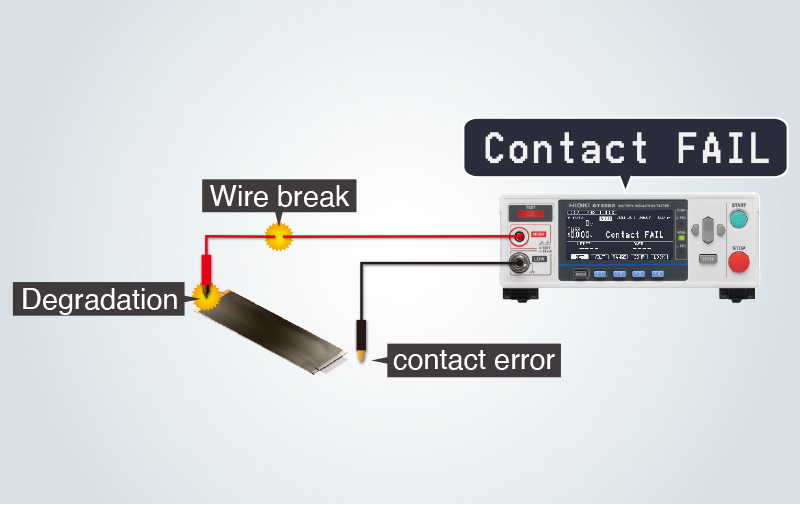

Preventing testing do-overs due to erroneous judgments

The BT5525 provides a contact check function to determine whether the instrument has made proper contact with the circuit under test by measuring the capacitance between the measurement terminals (stray capacitance and the capacitance of the circuit under test).

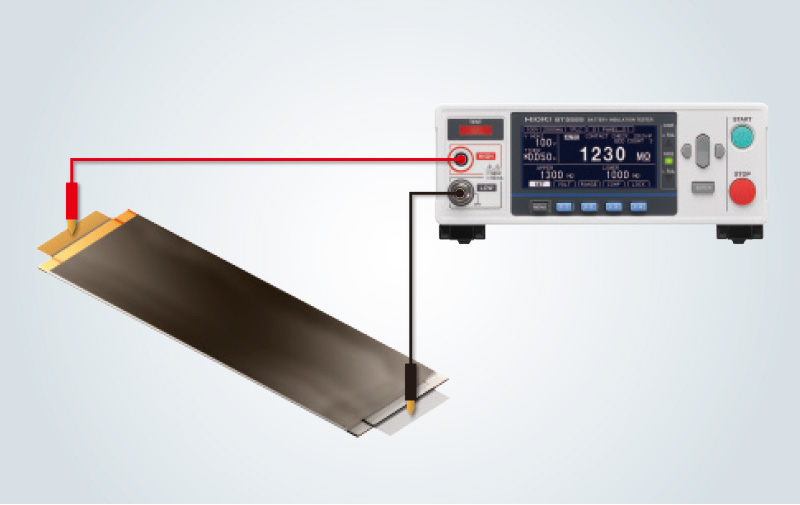

Ideal for insulation resistance testing before battery electrolyte filling

The BT5525 tests insulation between electrodes before cells are filled with electrolyte. Its maximum test voltage is 500 V. If certain test conditions are satisfied, it can also perform insulation testing between module/pack electrodes and the enclosure.

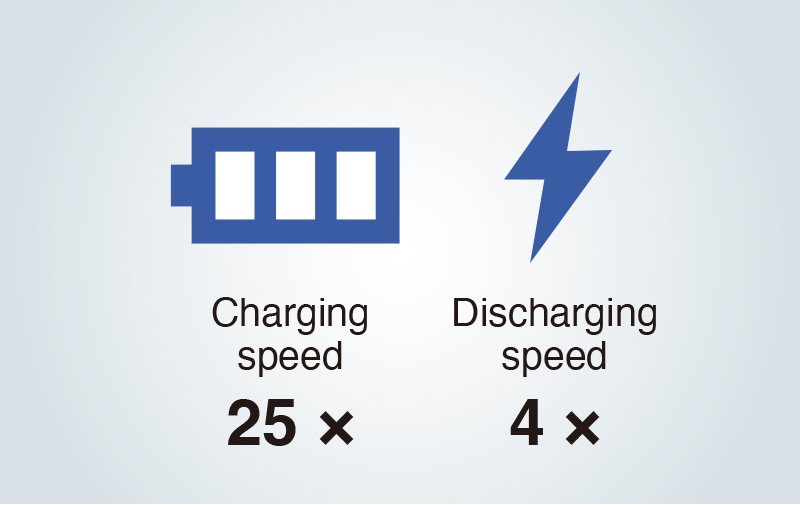

Shorten cycle times with a maximum charging current of 50 mA

The BT5525 features high-speed charging at up to 50 mA and high-speed discharging of residual charge at 40 mA. The instrument’s dramatically improved charging and discharging performance boosts testing speed, accelerating charging by about 25 times compared to previous models, and discharging by about 4 times. In this way, it can shorten insulation resistance testing times for batteries, which manufacturers are producing at ever-higher levels of capacity.

*Compared to Hioki’s INSULATION TESTER ST5520.

Invest in quality at a reasonable cost

The BT5525's functionality and performance make it a cost-effective solution due to careful consideration given to the demands of battery insulation resistance testing. Fluctuations in voltage and current during insulation resistance testing can be viewed using a dedicated PC application.

The instrument can output a test voltage of up to 500 V. The instrument satisfies insulation resistance testing conditions for everything from the large batteries used in electric vehicles (EVs) to small battery cells.

PC application for analyzing waveforms

A free PC application from Hioki can be used to review fluctuations in voltage and current.

The ability to review waveforms can be useful when analyzing test results and when determining judgment reference values for testing lines.

Since data can be output in the CSV format, waveforms can also be reviewed in other applications, for example Excel.

Das Produkt ist in folgenden Kategorien zu finden:

Batterietester Isolation bis 1kV Batterie-MessgeräteProduktgruppen

- Messtechnik

- Prüftechnik

- Labor

-

EMV+CE

- EMV- MESSEMPFÄNGER

- VSWR- Brücken

- EMV- Software

- Antennas + Tripods

- Absorber- Cabins and Rooms

- GTEM-, TEM- Cells, Stripline

- Automotive Pulse - ISO

- Automotive Board Net - LV

- E- Mobility

- Special- Generators (Telecom, Power- Net,...)

- Industry- Pulse

- Harmonics and Flicker

- ESD- Testing

- Magnetic Fields

- RF- Immunity Testsystems

- Amplifiers

- CDN, LISN, Probes, Clamps

- EMC / RF- Accessories, TEKBOX

- AC/DC Quellen-Lasten

- ESD

- CE-Prüfung

- Vorführgeräte

- Zubehör

- Aktionsprodukte